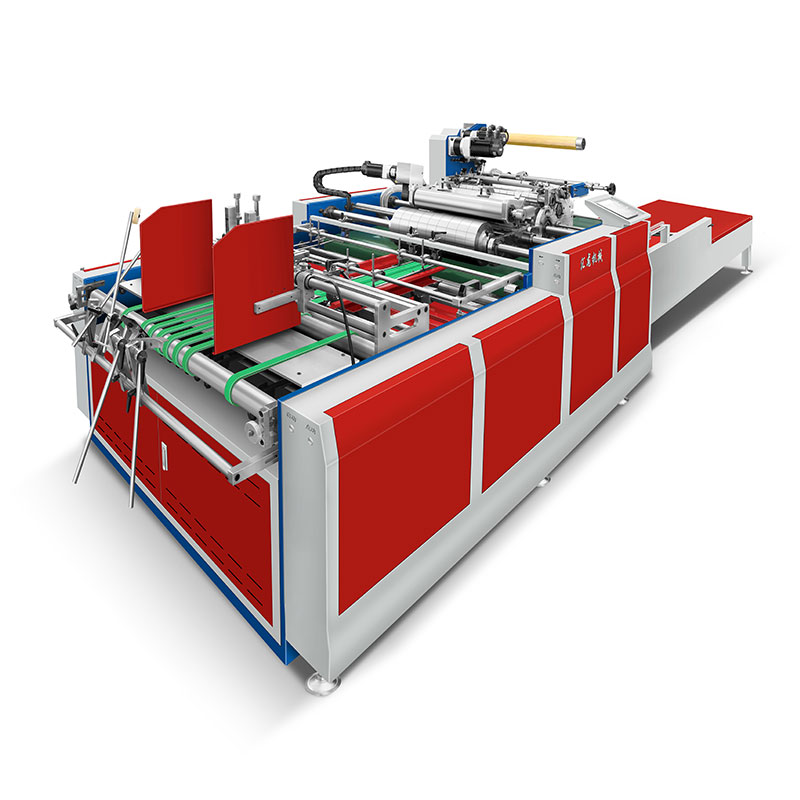

機(jī)器介紹Machine Introduction

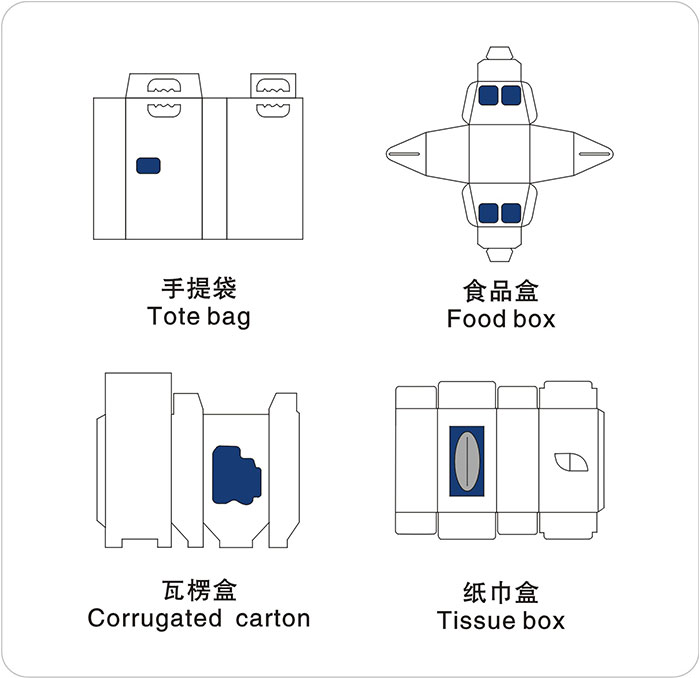

TC-1080D運(yùn)控型一拖二全自動高速靜音貼窗機(jī)適用于各種不同款式的開窗紙盒的窗口貼膜,具有如紙巾盒、禮品盒、玩具盒、化妝盒等,此設(shè)備具有高效、精準(zhǔn)、穩(wěn)定、易操作等特點(diǎn),能大大的提高生產(chǎn)效率,從而降低生產(chǎn)成本。它使用范圍廣,各種異形盒子也能快速操作,UV、白卡紙、瓦楞紙都適用。故該設(shè)備深受新老客戶青睞。

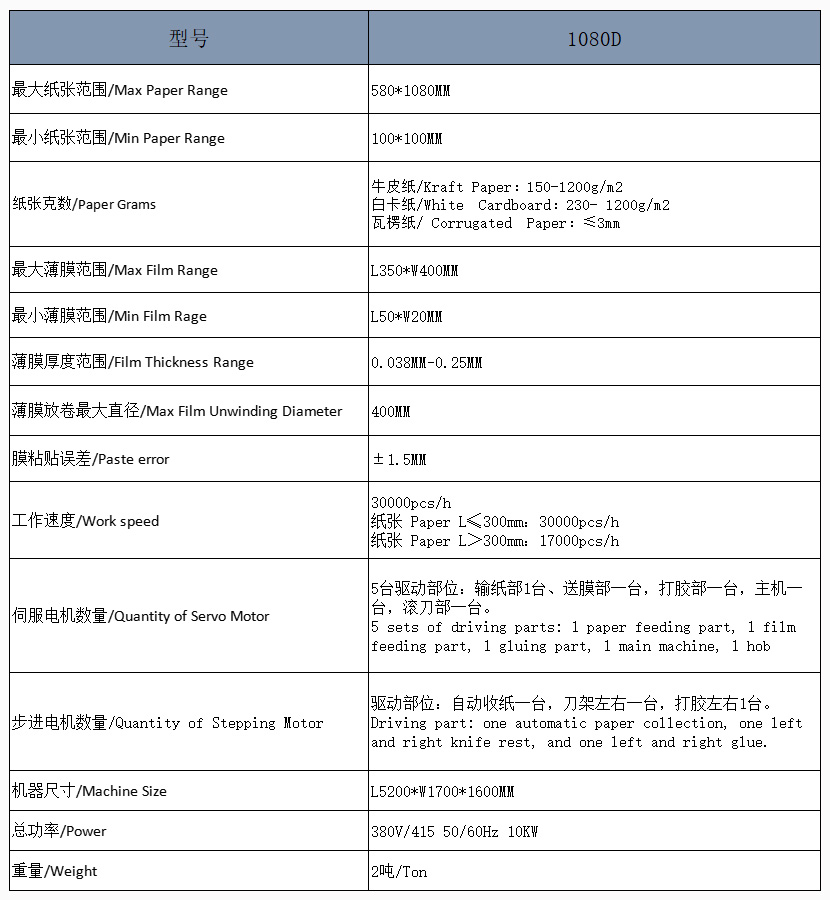

主要技術(shù)參數(shù)Specifications:

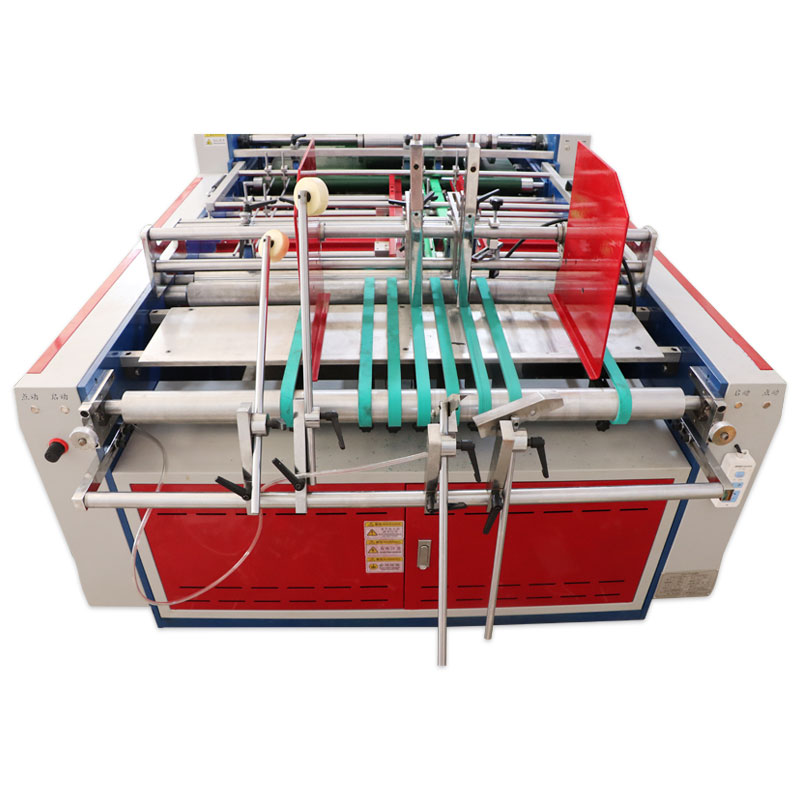

進(jìn)紙部Paper feeding department:

采用皮帶輸紙,適應(yīng)表面經(jīng)過覆膜,逆向UV,納米UV,油性及水性上光的紙張以及牛皮紙與瓦楞紙。

Adopt belt feeding paper,it is suitable for coated, reverse UV, nano UV, oily and waterborne paper, kraft paper and corrugated paper.

操作界面Operating interface:

所有參數(shù)的設(shè)置和功能的開關(guān)均在觸摸屏內(nèi)操作,操作面板外圍設(shè)有“點(diǎn)動,啟動,急停,調(diào)速”快捷操作按鈕。

All the parameters and functions of the switch areoperated in the touch screen, and the operationpanel is equipped with a "Inch, start, stop, speedadjust" quick operation button.

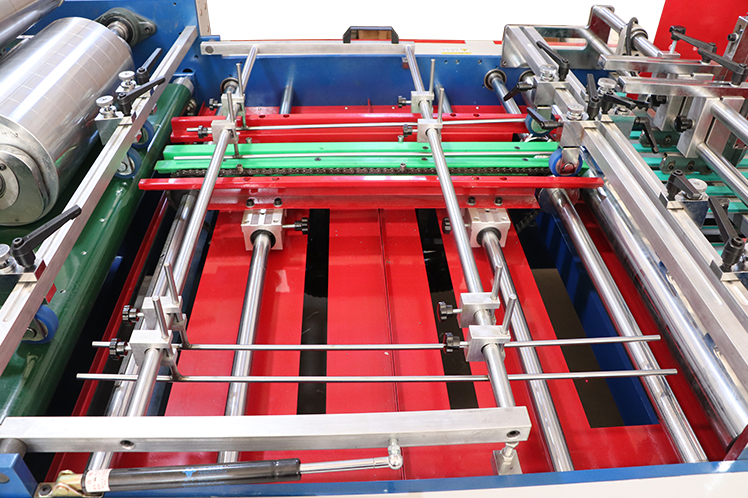

紙張校正軌道Paper correction track:

鏈條導(dǎo)條采用進(jìn)口高分子材料耐磨靜音,紙張定位采用四方推塊增加紙張高速運(yùn)行穩(wěn)定性。

Chain guides are made of imported polymer materials, wear-resistant and mute, and paper positioning is made of square pushers to increase the stability of paper in high-speed operation.

涂膠部Glue department:

涂膠滾筒采用304不銹鋼涂膠滾筒耐腐蝕,EVA海綿制作涂膠模型簡單造型任意,涂膠均勻,厚薄調(diào)節(jié)方便,卡位局部打膠節(jié)省膠水損耗,清洗方便。

The glue roller adopts 304 stainless steel glue roller which is corrosion-resistant. The glue model made of EVA sponge is simple and arbitrary. The glue is evenly spread, the thickness is easy to adjust, the glue is applied locally to the card position to save glue loss, and it is easy to clean.

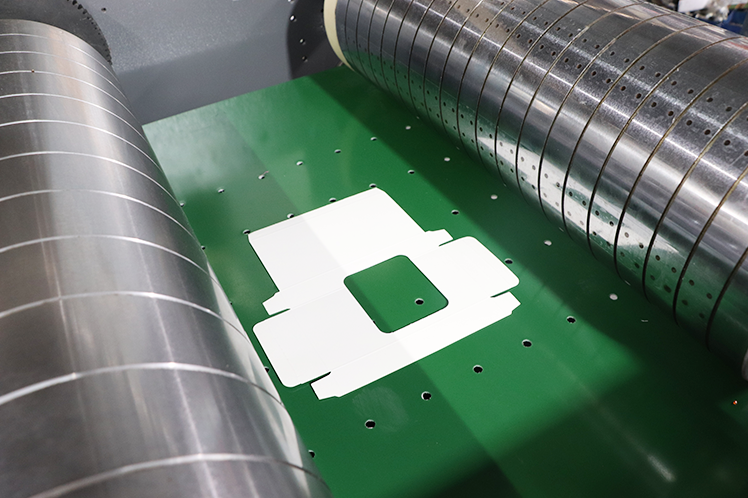

真空吸附Vacuum adsorption:

紙張?jiān)谕磕z與貼膜部位全程由打孔皮帶真空吸附,高速穩(wěn)定運(yùn)行,精度高。

Paper is vacuum absorbed by perforated belt in the whole process of gluing and pasting.It runs steadily at high speed and has high precision.

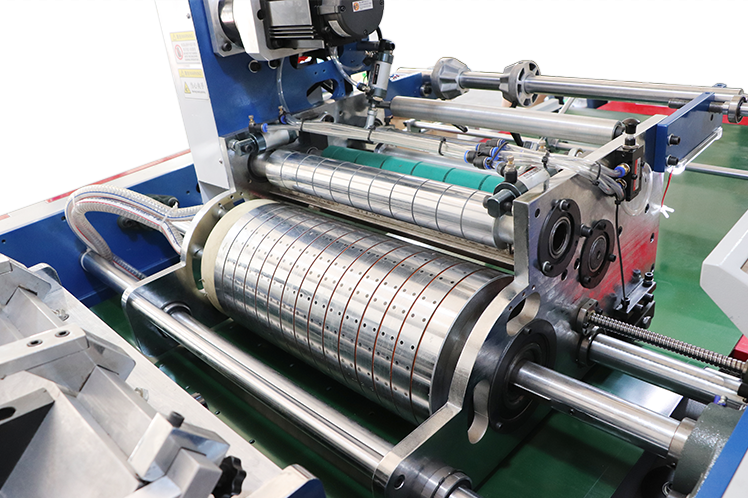

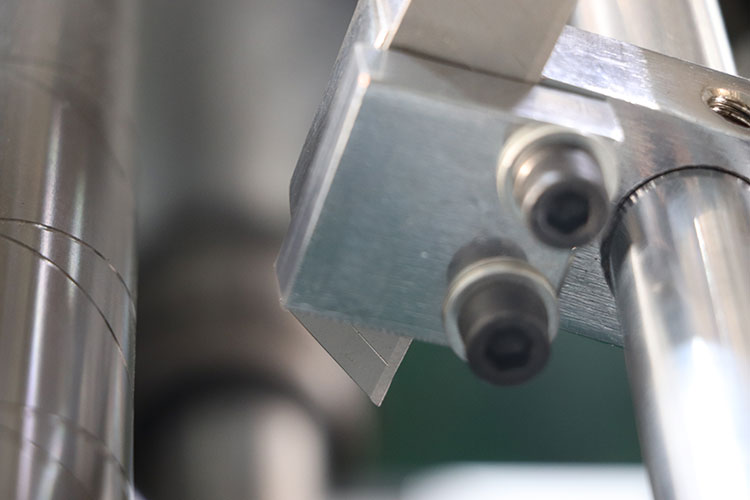

薄膜滾切與吸附Rolling cutting and absorbing of thin film:

切膜滾刀為局部分段式設(shè)計(jì),相比傳統(tǒng)整段式裁切噪音低,振動小,調(diào)刀換刀更方便,增加回力彈簧杜絕了卡刀問題的發(fā)生。

Film cutting hob is a local sectional design. Compared with traditional whole section cutting, it has lower noise, less vibration, more convenient tool adjustment and tool change. Adding back spring prevents the occurrence of stuck knife problem.

收紙部Paper collecting department:

單獨(dú)步進(jìn)電機(jī)控制收紙皮帶運(yùn)行,疊紙間距可整體或分段調(diào)節(jié),多段速運(yùn)行。

Single stepper motor controls the operation of paper-collecting belt. Paper-folding distance can beadjusted wholly or segmentally and run at multi-speed.

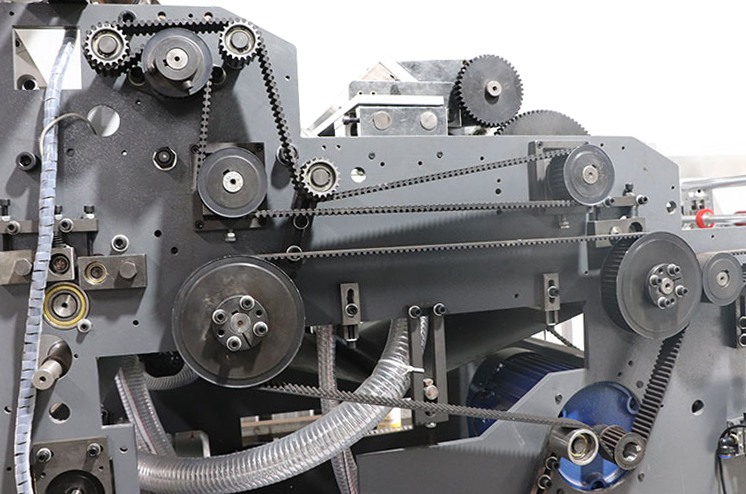

同步傳動Synchronized transmission:

所有傳動均采用同步輪同步帶傳動,機(jī)械噪音小,精度高。

All drives are driven by synchronous wheels and synchronous belts with low mechanical noise and high accuracy.

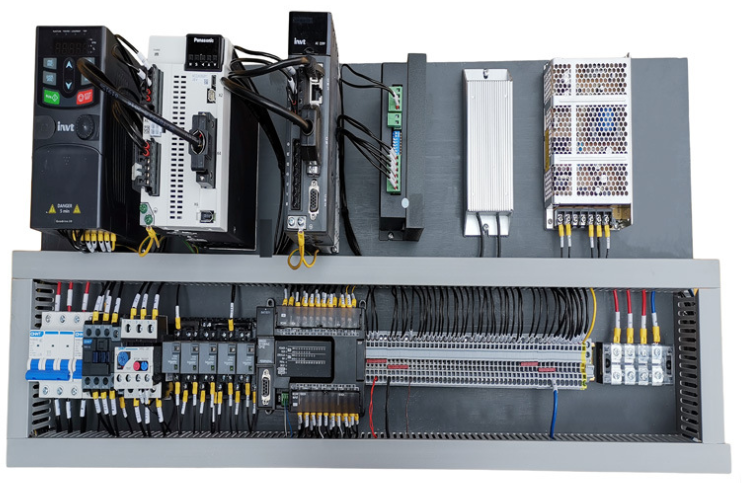

電氣控制Electrical control:

采用國際知名品牌,松下,英威騰,歐姆龍,施耐德等,精密度高,穩(wěn)定性好。

Adopting domestic listed companies' first-line brand "Xinjie" servo drive system and "lnovance" frequency conversion speed regulation system, the stability is high.

機(jī)器加裝項(xiàng)目Machine installation project:

1. 可加裝紙巾盒薄膜開口裝置,對薄膜局部進(jìn)行開口或切斷。

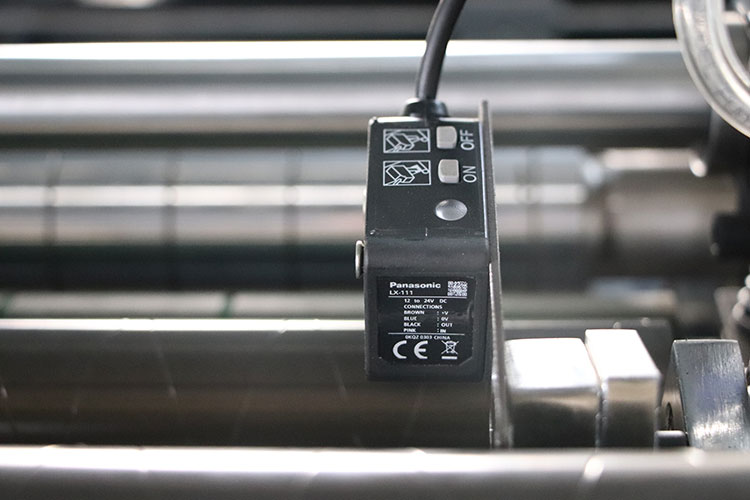

2. 可加裝針對薄膜有印刷的光標(biāo)跟蹤系統(tǒng),對薄膜印刷面圖案進(jìn)行跟蹤定位,窗口與薄膜圖案粘貼位置始終保持一致。

1. Paper towel box film opening device can be installed to open or cut off the local film.

2. A cursor tracking system for film printing can be installed to track and locate the pattern of film printing surface, and the position of window and film pattern sticking is always the same.

溫州匯龍印刷機(jī)械有限公司

![]() 聯(lián)系人:袁先生

聯(lián)系人:袁先生

![]() 手機(jī):15867701360

手機(jī):15867701360

![]() 座機(jī):0577-63515255

座機(jī):0577-63515255

![]() 傳真:0577-63515255

傳真:0577-63515255

![]() QQ:3790805814

QQ:3790805814

![]() 網(wǎng)址:www.winuu.com.cn

網(wǎng)址:www.winuu.com.cn